Difference between revisions of "American Crucible"

(→Latch Variations) |

(→Latch Variations) |

||

| Line 37: | Line 37: | ||

*This same style was also used with a stud and ESSCO-style thumbscrew. | *This same style was also used with a stud and ESSCO-style thumbscrew. | ||

*The cast tab and spring were sometimes replaced with a stamped metal piece and boot-shaped collar. | *The cast tab and spring were sometimes replaced with a stamped metal piece and boot-shaped collar. | ||

| − | <gallery mode=" | + | <gallery mode="nolines"> |

File:AmCr_Latch_LC.jpg|Stamped/Boot Style | File:AmCr_Latch_LC.jpg|Stamped/Boot Style | ||

</gallery> | </gallery> | ||

Revision as of 19:46, 4 January 2014

Contents

Corporate History and Overview

The American Crucible Products Company was formed in 1919. In 1926 it moved to Lorain, Ohio, and in 1928 began manufacturing traffic signals and flashing beacons. In 1939 a company called The Master Equipment Corp. was selling "Master" traffic lights and controllers. This link is still being investigated. At some point prior to WWII American Crucible stopped manufacturing traffic lights but are still operating today as part of BecoTek Mfg. U.S.A. Inc. They had a strong sales presence throughout Ohio including special installations in Bellevue, Dover, Hamilton, Salem, and Xenia. They had a smaller showing throughout the midwest but still had signals in Scranton, PA. and Muncie, In. Less notable installations were made in Ashland, Bedford, Bluffton, and Gallion, Ohio. They are also believed to have installations in Southern Michigan.

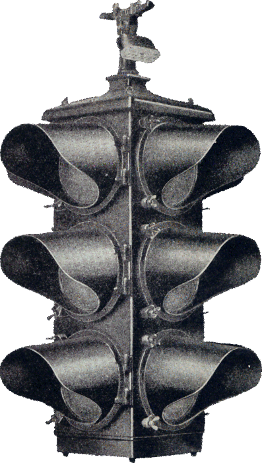

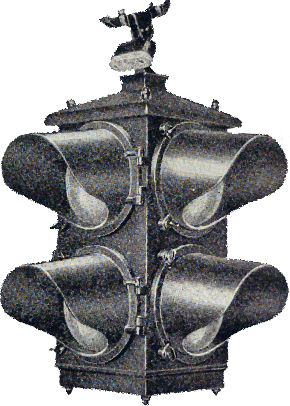

Traffic Signals

Design Characteristics

The traffic signals they produced were robust and had several notable design characteristics.

- Were said to have a sun phantom proof design.

- Early lights featured an angled bulb mount while later ones had the industry standard straight bulb configuration.

- Metal reflectors heavily chromium plated. Signals taken out of service 80 years later still have bright reflectors.

- Orange peel type lenses (the same styles used in Darley except a blue instead of green "green" lens.)

- Sealed, "dustproof" construction with lens and door gaskets.

- Early models featured cast cap visors, later signals were available with cast tunnel/circle visors and removable rolled aluminum visors.

- Signals with removable cast visors are the final version produced by the Traffic Master Company or The Master Equipment Corp. around 1939 in Amherst, Ohio.

- Marketed as "light weight" and weatherproof.

- Lights with a thin bottom plate were controlled externally, lights with a large bottom section had an integrated controller.

- Early signals were built from single piece side plates, later versions used used a stackable design to allow easy configuration of 1-4 signal sections.

Door Variations

During the course of production the most marked change to the signal was the branding as presented on the door.

- The earliest versions [1928-1930?] were of a solid body/cast visor design with no markings present on the door.

- Solid body/cast visor design with: THE MASTER SIGNAL THE AMERICAN CRUCIBLE PRODUCTS CO. LORAIN O. U.S.A.

- Cast visor sectional body style: THE MASTER SIGNAL U.S.A.

- Sectional body/removable rolled visor design with no markings present on the door.

- Sectional body/removable cast visors [1939?]: The Traffic Master Co Elyria O

Four Ways

Model S-3-29

Model S-2-29

This is the presumed model number for this variant.

Pedestrian Signals

describe models, variations

Vehicle Heads (Round)

describe models, variations

Vehicle Heads (Square Door Adapters)

describe models, variations

Pedestrian/Sign Heads (Rectangular)

describe models, variations

Informational Signals and Signs

describe models, variations [delete] includes "box signs," "case signs," and Ped Heads with special [non-ped] lenses.

Lenses

describe models, variations

Vehicular

The earlier lights used orange peel lenses, like used in Darley lights, except the green aspect was a blue lens, instead of a green lens. These were typically made by Jefferson or Brilliant.

Later lights used Corning Type-E Large Bead lenses.

Pedestrian

describe models, variations

Worded

describe models, variations

Symbols

describe models, variations

Special

describe models, variations

Controllers

- Split amber operation - only the green light traffic sees the amber.

- Single cam, induction motor mechanical controllers.

- Sealed gear system.

- Tungsten contacts with a sliding self cleaning action for longer life.

- Unique RED-I-FLASH system where a flashing red light above green indicates a signal change for two color signals.

- Single wire, impulse controlled coordination system.

- Masterless coordination system, any controller serves as master.

- Self lubricating bronze bearings.

- Positive starting in cold temperatures

Special Features Available:

- Emergency Control

- Manual Control

- Flashing or Night Amber mode

- Pedestrian Controls

- Coordination for Two and Three Period Controls

Hardware

This would include any kind of mounting hardware including brackets, slipfitters, hangers, bases, etc.

Miscellaneous Images

Various reference images, restored examples, etc. that don't fit anywhere else.

Relevant Patents

Patent numbers relevant to this MFR or signals specifically. Not just every patent by company X.

References

Insert any sources cited or used here