Difference between revisions of "Tokheim"

(→Standard Controller Cabinet) |

(→Early Tokheim Designs) |

||

| Line 37: | Line 37: | ||

Tokheim signals also had several build options available as documented in the hardware section. | Tokheim signals also had several build options available as documented in the hardware section. | ||

| + | |||

| + | The design and construction of the Tokheim signal was pretty standard. The basic 4-way light was built of cast aluminum plates assembled into a box section (earlier lights used a single plate per side, later lights would use one plate per aspect.) The sides featured little in ornamentation, the borders were raised while the remaining side face was recessed save for a proud lip to mate with the door. Both the top and bottom were simple affairs, a rounded pizza box square. The bottom featured a flower patterned rain drain however this still remained the weak point of the signal. Despite numerous examples surviving 80+ years in service in good health almost every bottom plate would stress crack or suffer the effects of moisture rot long before, requiring an inservice retrofit. | ||

| + | |||

| + | Adjustable signals were similar, a two piece design consisting of a curved tub for the back of the housing and a flat front plate which mounted to it, though not interchangeable with the 4-way plate. Later adjustables would be built in sections - one per lens. | ||

| + | |||

| + | The reflector mount was integrally cast into this side plate, set back in a deep recess. The reflector itself was a two piece affair: a black enamel steel bowl which mounted to the body with a twist-on screw-and-eyelet design into which was set a thick mirrored glass reflector. A standard keyless porcelain front mount/back wired socket would mount to the reflector bowl. Similar sockets were used in may other signals of the era, CH Type-T, Harrington Seaberg, etc. It would be a few decades before manufacturers would consider the custom phenolic socket route. | ||

| + | |||

| + | The porthole doors were an intricate affair. Molded with architectural flair, the porthole would mount to the body via two thick hinge bosses permanently pinned to a thick piece of U-channel steel, the U-channel being bolted to the body of the signal. Early doors had four ears to hold captive thumbscrews, similar to a Harrington-Seaberg. The later style did not require ears as the unequal brass studs were mounted to the body upon which rested a large steel spring, one of several variations of l-bracket latches, and a wingnut. The face of the door would have four plinths to catch these wingnut-brackets - typically only two would be used but the alternates could come in handy when used with angled door adapters. Rounding out the exterior of the door was a deep inset for the lens. This allowed for inset mounting of the visor. On the reverse of the door was a series of steppes and grooves. The outermost held a feltlike gasket to seal the lampholder against dust. Rising far from this was a crown ring that formed both mounting bosses for the steel/brass lens retainer clips as well as provided a small lip to hold the lens/felt lens gasket into position. | ||

====Later Tokheim Designs==== | ====Later Tokheim Designs==== | ||

Revision as of 16:54, 4 January 2014

Contents

- 1 Corporate History and Overview

- 2 Traffic Signals

- 2.1 Design Characteristics

- 2.2 Four Ways

- 2.3 Adjustables

- 2.3.1 Early Tokheim Signals

- 2.3.2 Later Tokheim Signals

- 2.3.2.1 Cut 1310 - One-Way, Post-Type, Traffic Control Signal

- 2.3.2.2 Cut 1400 - Horizontal Adjustable Post Bracket, Traffic Control Signal

- 2.3.2.3 Cut 1406 - One-Way, Vertical-Bracket Type, Traffic Control Signal

- 2.3.2.4 Cut 1410 - Vertical Adjustable Post Bracket, Traffic Control Signal

- 2.3.2.5 Sectional Signals

- 3 Pedestrian Signals

- 4 Informational Signals and Signs

- 5 Lenses

- 6 Controllers

- 7 Hardware

- 8 Miscellaneous Images

- 9 Relevant Patents

- 10 References

Corporate History and Overview

Following the February 1898 design of a gas pump by John J. Tokheim the Tokheim Manufacturing Company was incorporated in Cedar Rapids, Iowa in 1901. In 1918 employees of the Wayne company set out on their own, purchasing Tokheim and reincorporating it as the Tokheim Oil Tank and Pump Company, moving to Fort Wayne, Indiana in the old Wayne Spoke and Bending Company factory. In April 1926 they acquired the Signaphore company, also located in Fort Wayne, and formed the Tokheim Traffic Signal Division - although such branding has not been seen on their products, instead retaining the TOT&PCo. nomenclature. This acquisition brought along J. N. Paul of Automatic Signal Co. and Ruben E. Bechtold, from Signaphore. They would greatly develop and expand the Signaphore line into the modern traffic signal as well as introduce new controllers. By 1937 their interest in the product line waned and on January 8th, 1938 the transition of their signal interests both in design and manufacturing to Automatic Signal of East Norwalk, Connecticut, took place, along with pioneering traffic engineer Reuben E. Bechtold. [1]

Traffic Signals

Design Characteristics

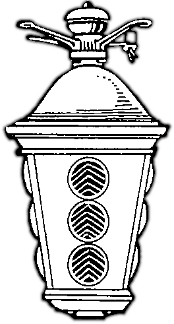

Signaphore Era

When the Signaphore line was acquired they were producing novel 4-way traffic signal standards that appeared much like a round bodied gas pump with a traffic light on top. Like many manufacturers of the day they produced signals out of both aluminum and copper, later switching to all aluminum. Quite popular locally, they attracted the attention of Detroit, who requested pole-mount versions of the signal. Adjustable traffic signals would follow, and their market spread throughout the midwest including such cities as Cleveland, Chicago, and Detroit. It has been said they entered the international market too, however little is known of that.[1]

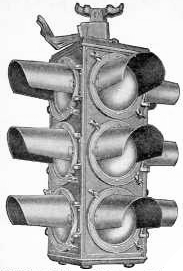

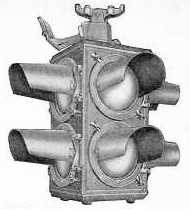

For a brief period of time following the acquisition of Signaphore, Tokheim produced an intricate appearing four-way signal available in both aerial and post mount versions. It is believed this type only existed through 1925 as Tokheim quickly implemented their own designs.

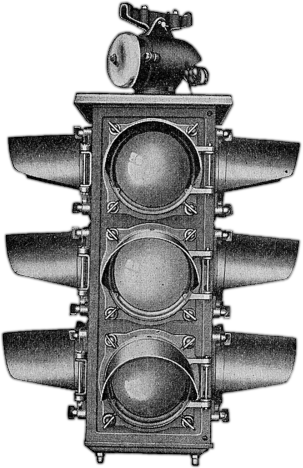

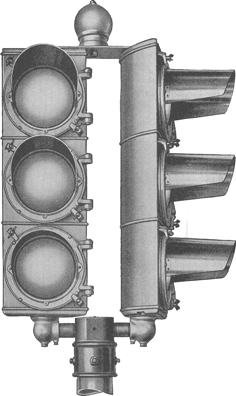

Early Tokheim Designs

In 1926 Tokheim begin to advertise traffic signals of a revised design that had the same basic design that would continue through the end of their product line. The primary difference in these signals was the design of the porthole door. In the early signals it was a door hinged to the body while held down with four thumbscrews protruding through ears on the door. Later signals would simplify this door design, remaining hinged but changing it to a full circle (removing the thumbscrew ears) and locking it down via only two body mounted studs with springs, L-brackets, and wingnuts mounted to the upper left and lower right of the door - although the body casting and door castings would contain provisions for four hold down tabs. The visors maintain the same profile, however the earlier ones appear to be cast and either integral or bolted to the door.

All Post-Signaphore Tokheim signals were designed with several characteristics:

- All bodies are of cast aluminum

- Felt gaskets are used on the lense and door

- Doors are portholes held in place with two L-clamps and wingnuts

- All visors were cutaways with 8" length

- Reflectors are thick glass with an electrolytic copper plating

- Reflectors are held in a pan and mounted to the signal body

- Sockets are a porcelain Leviton wing style

- Wiring is done with rubber wire

- Lamps are 50-Watt mill or 60-Watt traffic bulbs

Tokheim signals also had several build options available as documented in the hardware section.

The design and construction of the Tokheim signal was pretty standard. The basic 4-way light was built of cast aluminum plates assembled into a box section (earlier lights used a single plate per side, later lights would use one plate per aspect.) The sides featured little in ornamentation, the borders were raised while the remaining side face was recessed save for a proud lip to mate with the door. Both the top and bottom were simple affairs, a rounded pizza box square. The bottom featured a flower patterned rain drain however this still remained the weak point of the signal. Despite numerous examples surviving 80+ years in service in good health almost every bottom plate would stress crack or suffer the effects of moisture rot long before, requiring an inservice retrofit.

Adjustable signals were similar, a two piece design consisting of a curved tub for the back of the housing and a flat front plate which mounted to it, though not interchangeable with the 4-way plate. Later adjustables would be built in sections - one per lens.

The reflector mount was integrally cast into this side plate, set back in a deep recess. The reflector itself was a two piece affair: a black enamel steel bowl which mounted to the body with a twist-on screw-and-eyelet design into which was set a thick mirrored glass reflector. A standard keyless porcelain front mount/back wired socket would mount to the reflector bowl. Similar sockets were used in may other signals of the era, CH Type-T, Harrington Seaberg, etc. It would be a few decades before manufacturers would consider the custom phenolic socket route.

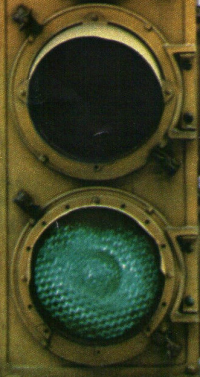

The porthole doors were an intricate affair. Molded with architectural flair, the porthole would mount to the body via two thick hinge bosses permanently pinned to a thick piece of U-channel steel, the U-channel being bolted to the body of the signal. Early doors had four ears to hold captive thumbscrews, similar to a Harrington-Seaberg. The later style did not require ears as the unequal brass studs were mounted to the body upon which rested a large steel spring, one of several variations of l-bracket latches, and a wingnut. The face of the door would have four plinths to catch these wingnut-brackets - typically only two would be used but the alternates could come in handy when used with angled door adapters. Rounding out the exterior of the door was a deep inset for the lens. This allowed for inset mounting of the visor. On the reverse of the door was a series of steppes and grooves. The outermost held a feltlike gasket to seal the lampholder against dust. Rising far from this was a crown ring that formed both mounting bosses for the steel/brass lens retainer clips as well as provided a small lip to hold the lens/felt lens gasket into position.

Later Tokheim Designs

These signals were intorduced in 1927 and are believed to use the same housing as the early Tokheims with a new style door and visor. Otherwise the construction is believed identical.

Four Ways

Signaphore Signals

Early Tokheim Signals

Cut 1110 - Aerial Traffic Control Signal

A precursor to the Cut 1200, as shown, equipped with a bell.

Cut 1112 - Dual Traffic Control Signal

A precursor to the Cut 1300

Later Tokheim Signals

Cut 1200 - Four-Way Aerial Traffic Control Signal

Cut 1260 - Four-Way, Two Color, Aerial Traffic Control Signal

No Yellow/Caution Lens

Cut 1300 - Four-Way, Post-Type, Traffic Control Signal

Sectional Signals

At some time, 4-way sectional heads were also made.

Adjustables

Early Tokheim Signals

Cut 1170 - Vertical Traffic Control Signal

Precursor to the Cut 1410

Cut 1171 - Horizontal Traffic Control Signal

Precursor to the Cut 1410

Later Tokheim Signals

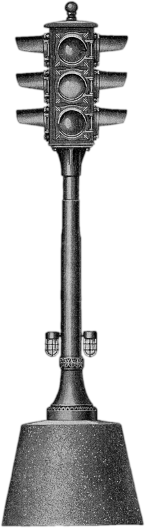

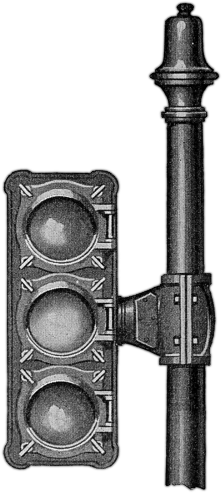

Cut 1310 - One-Way, Post-Type, Traffic Control Signal

Also available in two to five way clusters. Solid Body

Figure: Tokheim 1310 Signal. [Image by LC]

Cut 1400 - Horizontal Adjustable Post Bracket, Traffic Control Signal

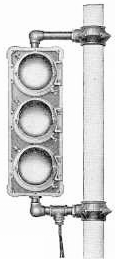

Cut 1406 - One-Way, Vertical-Bracket Type, Traffic Control Signal

Also available in two to four way clusters. Solid Body

Cut 1410 - Vertical Adjustable Post Bracket, Traffic Control Signal

Sectional Signals

This is a sectional signal head made by Tokheim.

Pedestrian Signals

Vehicle Heads (Round)

Tokheim did not manufacture any pedestrian signals.

Vehicle Heads (Square Door Adapters)

Tokheim did not manufacture any pedestrian signals.

Pedestrian/Sign Heads (Rectangular)

Tokheim did not manufacture any pedestrian signals.

Informational Signals and Signs

describe models, variations [delete] includes "box signs," "case signs," and Ped Heads with special [non-ped] lenses.

Lenses

Vehicular

Lenses are 8 3/8" dia. with a 90° diffusing pattern. Command lenses are optional, with embossed letters two inches high, and a baked enamel finish.

Pedestrian

describe models, variations

Worded

describe models, variations

Symbols

describe models, variations

Special

describe models, variations

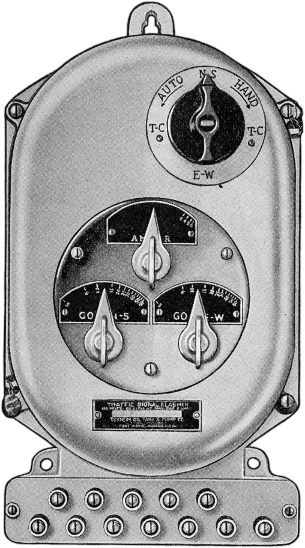

Controllers

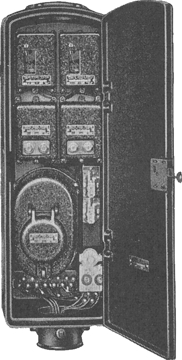

Controllers were individually settable for the Red, Yellow, and Green phases. Stop and Go could be set for anywhere from 15 sec. to 3 minutes. The clearance, yellow, could be set from two seconds to approximately ten seconds.

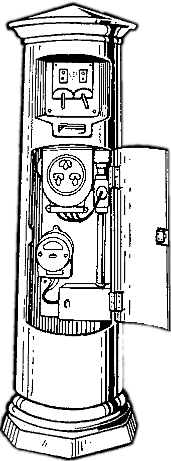

Signaphore Controllers

The early controllers were either inherited from Signaphore or developed shortly thereafter. Not surprisingly, the early units were housed in a cast iron tube resembling the base of a gasoline pump.

Cut 2000 - Chronoplan

Not a controller in itself, but the Tokheim guide on installation and setup of a traffic controller system utilizing a Chronolizer and several 1500 Timer modules. Improvements of up to 94% over the synchronized system and 43% over the staggered controller systems were guaranteed for a car doing the speed limit.

Chronolizer - Central Controller

This was a device attached to a series of 1500 timers to control a full roadway of signals in interoperation and coordination. It would set the cycle period for each individual controller which still had independent control over the timing of its red/[amber]/green split times. More than 1000 of these systems were reported in operation by 1928, reportedly improving the average speed of traffic flow "by 94% over a synchronized system or 43% over a stagger system."

Cut 1500 - Traffic Signal Timer

Introduced in 1925, the model 1500 was a local timer for controlling traffic signals.

Cut 1550 - Universal Traffic Signal Timer

Available NLT 1931, the Cut 1550 was an improved version of the 1500. It was marketed as a universal timer in so much that it provided a large variety of terminal posts for signal wiring and by a combination of connections primarily dealing with yellow overlaps during the phase change in both directions. Tokheim provided a two year warranty on this product.

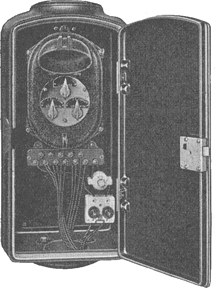

Cut 1820 - Automatic Traffic Signal Control

The model 1820 was essentially a 1500 timer and associated circuitry in a cabinet to allow isolated operation of a single signal or intersection.

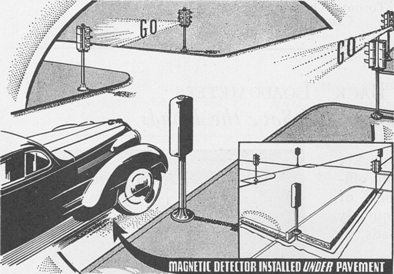

Magnetic Detector

Part of the later signal line upgrades included early magnetic detectors for vehicle-actuation. Following is an example of the controller with magnetic detection modules and a marketing image of an intersection configured as such.

Figure: Tokheim magnetic detectors. [Image by LC]

Hardware

Tokheim had several modification kits that could be installed on the standard Cut traffic signals. These were used primarily on the 4-way signals.

- Blank covers were available as an option on one to three sides of a light.

- Angled door adapters were available in offsets of 15°, 30°, or 45°.

- The standard wire entrance hanger could be supplemented with a Traffic Bell that would ring during the amber change period.

- Possibly a downlight or bell mount bottom cover was available.

- In the post-Signaphore era it is believed Tokheim made only one kind of visor, a rolled aluminum sheet cap with rivited on brass or steel triangular tabs. This same visor was available with a perforated lip in place of the triangular tabs allowing rudimentary use as an adjustable, view limiting device. In the accompanying photo, used in a print advertisement for an oil company illustrates the standard visor (on the amber light) and the adjustable visor (on the green aspect.)

- Where mounting features were not required but present (such as a post mount 4-way) a finial resembling a ball doorknob was often used.

.

Miscellaneous Images

.

Relevant Patents

Inventor Company Number Date, Filed Date, Issued Desc Link

R. E. BECHTOLD Tokheim Oil Tank and Pump Company 1926833 26-Apr-26 12-Sep-33 Tokheim Signal Controller http://www.google.com/patents?id=rDpCAAAAEBAJ

R. E. BECHTOLD Tokheim Oil Tank and Pump Company 1951816 31-Jul-28 20-Mar-34 Synchronized Controller System http://www.google.com/patents?id=7JZXAAAAEBAJ

References

[1] Back to the Future Tokheim, Bob Lee, 1993, ISBN 0-9638220-0-4